Should I Wear a Mask When Soldering to Protect Against Flux Fumes?

Posted by Sam Tucker on 27th Sep 2024

Should I Wear a Mask When Soldering to Protect Against Flux Fumes?

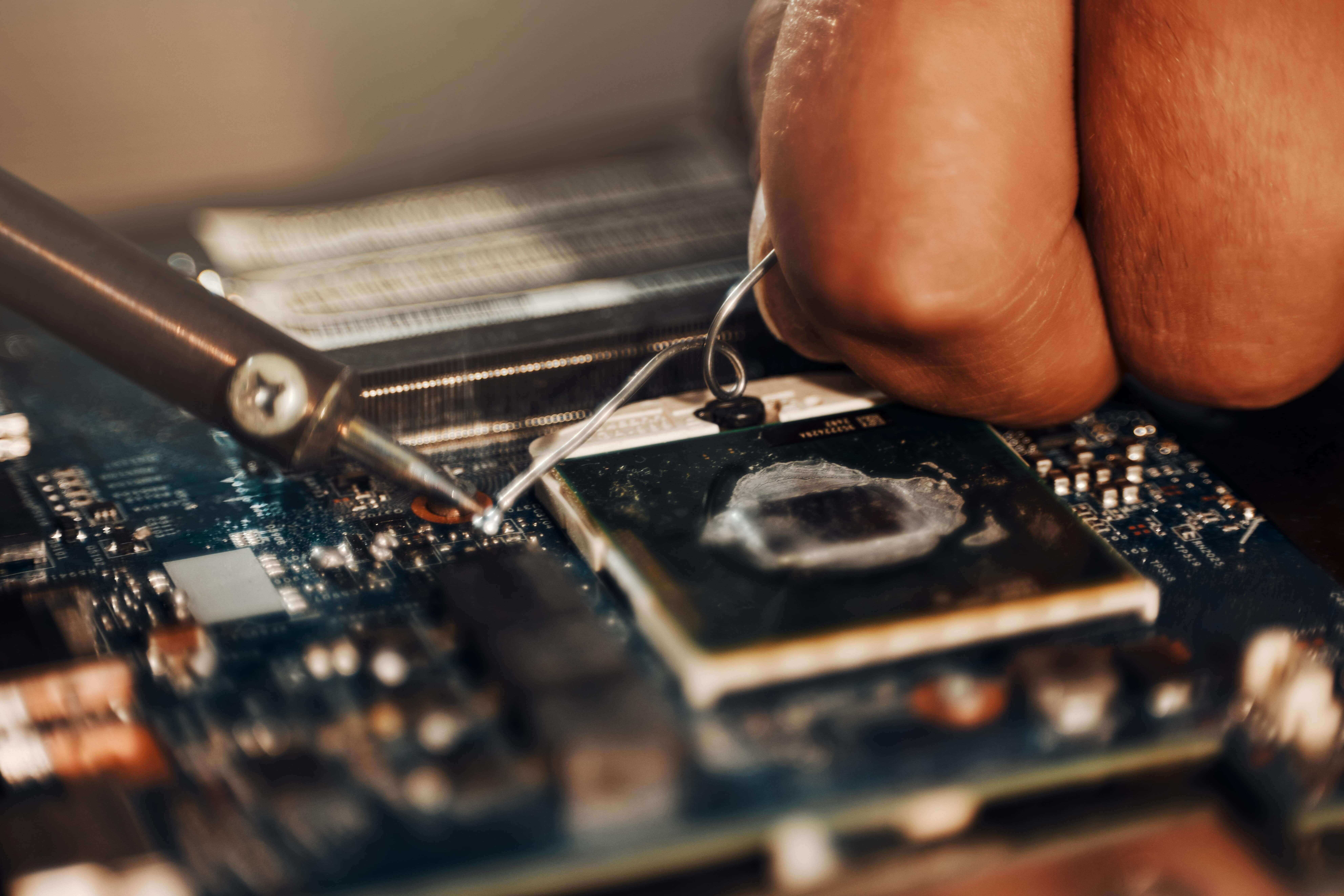

Whether or not you should wear a mask when soldering depends on several factors, including the type of soldering being performed, the materials being used, and the ventilation of the workspace. In general, it’s a good idea to wear a mask when soldering to protect yourself from inhaling harmful fumes, particularly those produced by flux.

Why Wear a Mask When Soldering?

One of the main reasons to wear a mask when soldering is to protect yourself from inhaling harmful fumes. Soldering produces fumes from both the solder and the flux, which can be dangerous to your respiratory system if inhaled. Flux fumes are especially concerning, as they can contain substances that irritate the lungs and may lead to long-term health issues like asthma or even lung damage. To protect yourself from these hazards, it’s important to wear a mask to filter out harmful fumes directly.

Harmful Particles From Soldering

Beyond fumes, some soldering processes, such as wave soldering, can also generate fine particles of solder or flux that can be inhaled. These particles can cause damage to the respiratory system over time if inhaled in significant quantities. To protect yourself from these hazards, it’s recommended to wear a mask designed to filter out fine particles, such as an half mask with A2 gas/vapour filter + P3 particulate filter:

7502

6051 A2

5935 P3R

plus 501 retainer

Protection From Heat and Radiation

Another reason to wear a mask when soldering is to protect yourself from the heat and radiation produced by the soldering iron. Soldering irons can generate intense heat and emit ultraviolet (UV) and infrared (IR) radiation. Exposure to these elements can cause burns, eye damage, and other health issues if not properly shielded. In this case, wearing a mask that provides some level of protection from heat and radiation, such as a full-face respirator, is essential.

3M 6800

Additional Factors to Consider

When deciding whether or not to wear a mask while soldering, it’s also important to consider other factors, including:

- Type of Soldering: Some soldering techniques, like wave soldering or reflow soldering, produce more fumes and particles than others. For such processes, wearing a mask is particularly important.

- Materials Used: Certain solders and fluxes produce more harmful fumes than others. If you’re working with materials known to be hazardous, it’s especially important to wear appropriate respiratory protection.

- Workspace Ventilation: The ventilation in your workspace plays a crucial role. In a well-ventilated area, the concentration of fumes and particles will be lower. However, in poorly ventilated spaces, fumes can accumulate, making the use of a mask more critical.

Beyond the Mask: Other Safety Measures

While wearing a mask is an important safety measure, it’s not the only step you should take to protect yourself when soldering:

- Work in a Well-Ventilated Area: Make sure your workspace has good airflow. Open windows, use fans, or employ other ventilation equipment to reduce the concentration of fumes and particles.

- Use a Fume Extractor: A fume extractor can capture and remove fumes and particles before they enter the air you breathe. This greatly reduces exposure to harmful substances.

- Personal Protective Equipment (PPE): In addition to a mask, wear gloves to protect your hands from burns and safety glasses to shield your eyes from heat and radiation.

Conclusion

It’s a good idea to wear a mask when soldering to protect yourself from harmful flux fumes, fine particles, and the heat and radiation produced by soldering equipment. However, wearing a mask is just one part of a comprehensive safety approach. Working in a well-ventilated area, using a fume extractor, and wearing PPE will further ensure that your soldering work is both safe and effective.

---

Disclaimer: We are happy to offer guidance based on general guidelines and industry best practices. However, please note that our advice may not cover all specific conditions related to your particular usage, work environment, or local regulations.

We strongly recommend that you refer to your organization’s safety protocols, manufacturer recommendations, and relevant Safety Data Sheets (SDS) for precise instructions. While we are here to assist, the ultimate responsibility for determining when to replace parts and accessories lies with your team. We cannot be held liable for any decisions made based on our recommendations.